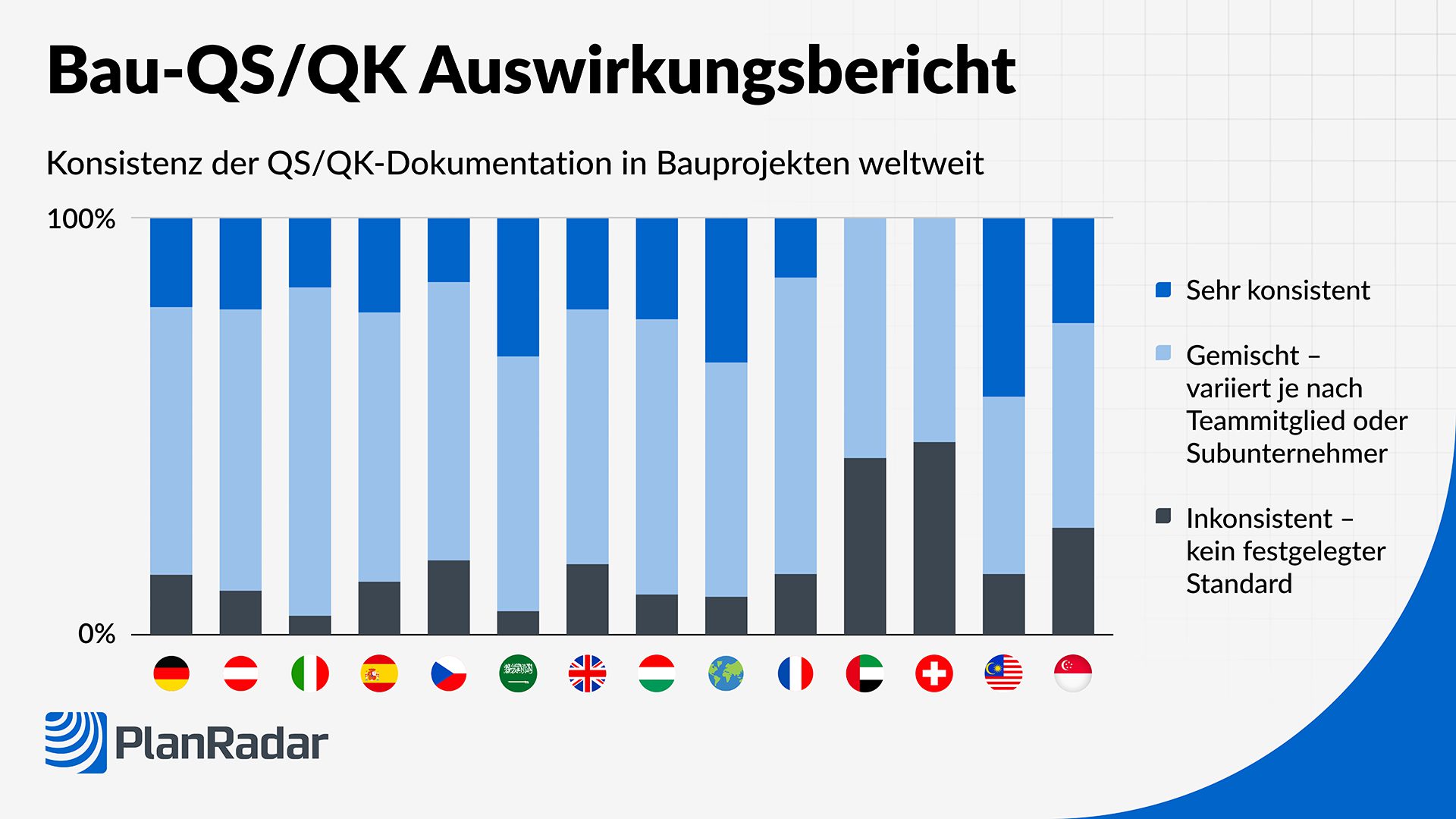

A new study by PlanRadar, a leading platform for digital documentation, communication and reporting in construction, facility management and real estate projects, shows that a lack of consistency in quality management (QA/QC) is putting the construction industry under massive pressure. Although more than 70 percent of companies state that they rely on QA/QC from day one, 77 percent report inconsistent standards between projects, locations and trades. The consequences are serious: inefficient processes drive up costs, lead to delays in deadlines and exacerbate disputes between clients, construction companies and subcontractors. The industry-wide enforceability of standards is particularly difficult – more than half of those surveyed do not have any binding requirements.

For the “Construction QA/QC Impact Report”, PlanRadar surveyed 811 professionals from 13 countries in Europe, the Middle East and the Asia-Pacific region – including project and construction managers, general contractors, specialist trades, architects as well as developers and owners.

Lack of standards causes high costs

The results make it clear that quality defects in the construction industry have far-reaching consequences. Two-thirds of respondents see QA/QC errors as the cause of project delays, and nearly 60 percent report that these delays average more than two weeks. Companies without defined QA/QC standards are also almost twice as likely to have no visibility into rework costs than those with clear processes. In addition, the study shows that companies without uniform QA/QC processes are more likely to face warranty claims and disputes with subcontractors.

At the same time, the advantage of consistent procedures becomes clear: Companies with systematic quality management report margins of more than three percent much more often and are significantly better able to keep rework within budget.

“QA/QC is a top priority for the industry. The challenge is consistency,” says Bojan Petkovic, Head of Sales Europe at PlanRadar. “Our survey shows that when each location and trade operates according to a different set of rules, the quality results become random and the costs incalculable. The way forward is through consistent, enforceable QA/QC standards.”

Focus on Germany: Uniform standards as a success factor

The international results are also reflected in the German construction industry. In particular, construction companies that work with a large number of subcontractors report unclear responsibilities, increased rework costs and a lack of cost transparency. Industry experts therefore emphasize that digitally supported, standardized QA/QC processes are crucial to secure margins, stabilize construction times and reduce liability risks.

The study makes it clear that the industry is almost unanimously focused on optimization: 78 percent of respondents are convinced that stronger QA/QC would improve profitability. The results make it clear that quality assurance is not only a question of compliance, but has a direct impact on cost control and project success. In view of rising costs, growing project complexity and increasing competitive pressure, the consistent implementation of uniform standards is becoming a crucial prerequisite for the sustainable success of construction companies.

The full report can be found on the PlanRadar website.